Safety technology by HPZ for track construction sites

When working on railway tracks, personnel have to be protected from the dangers of railway operations. The best measure is, of course, to close the track. However, since a track closure is not always possible, HPZ GmbH offers a solution – e.g. with the fixed barrier UPZ III EN – which separates the workers from railway operations and thereby offers the highest degree of safety and protection. Moreover, HPZ GmbH allows you to benefit from technical aids to support crossing points, electrical signallers, the signalling of speed restrictions and much more. HPZ GmbH thus delivers the highest safety standards for protecting track construction sites.

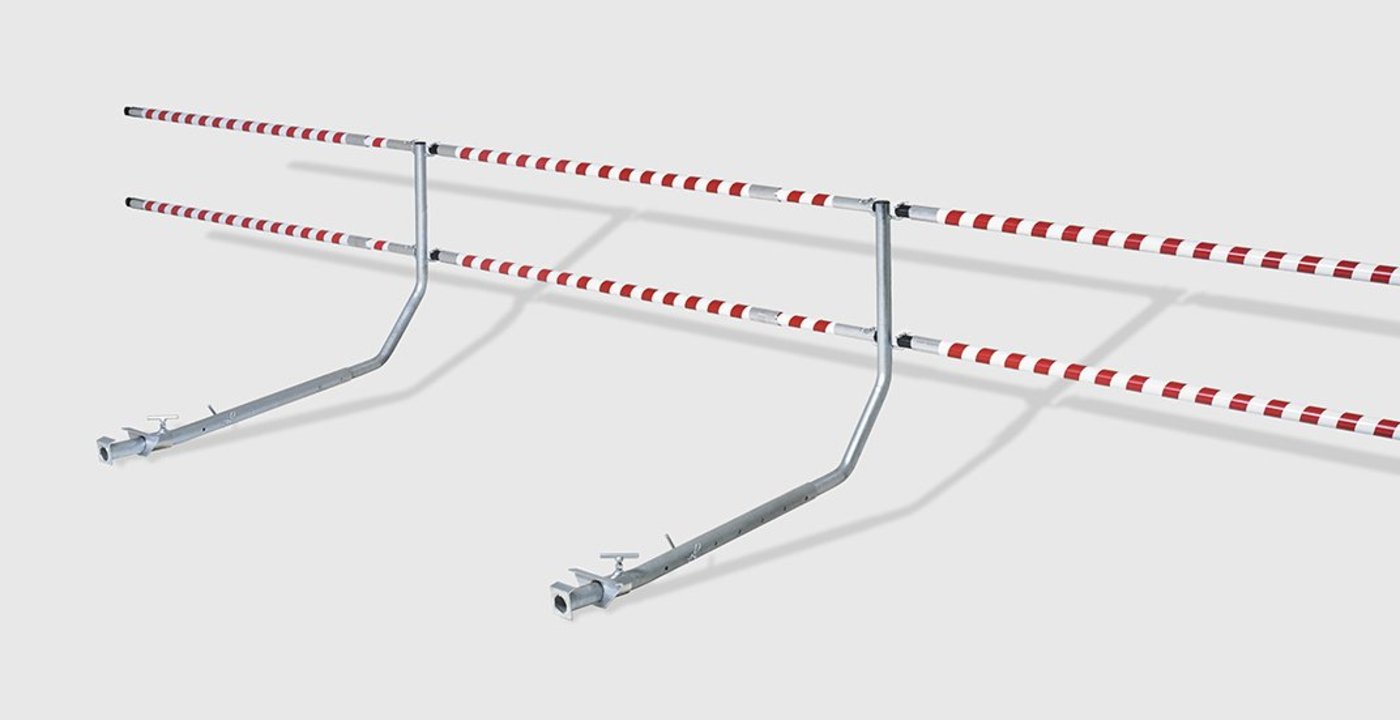

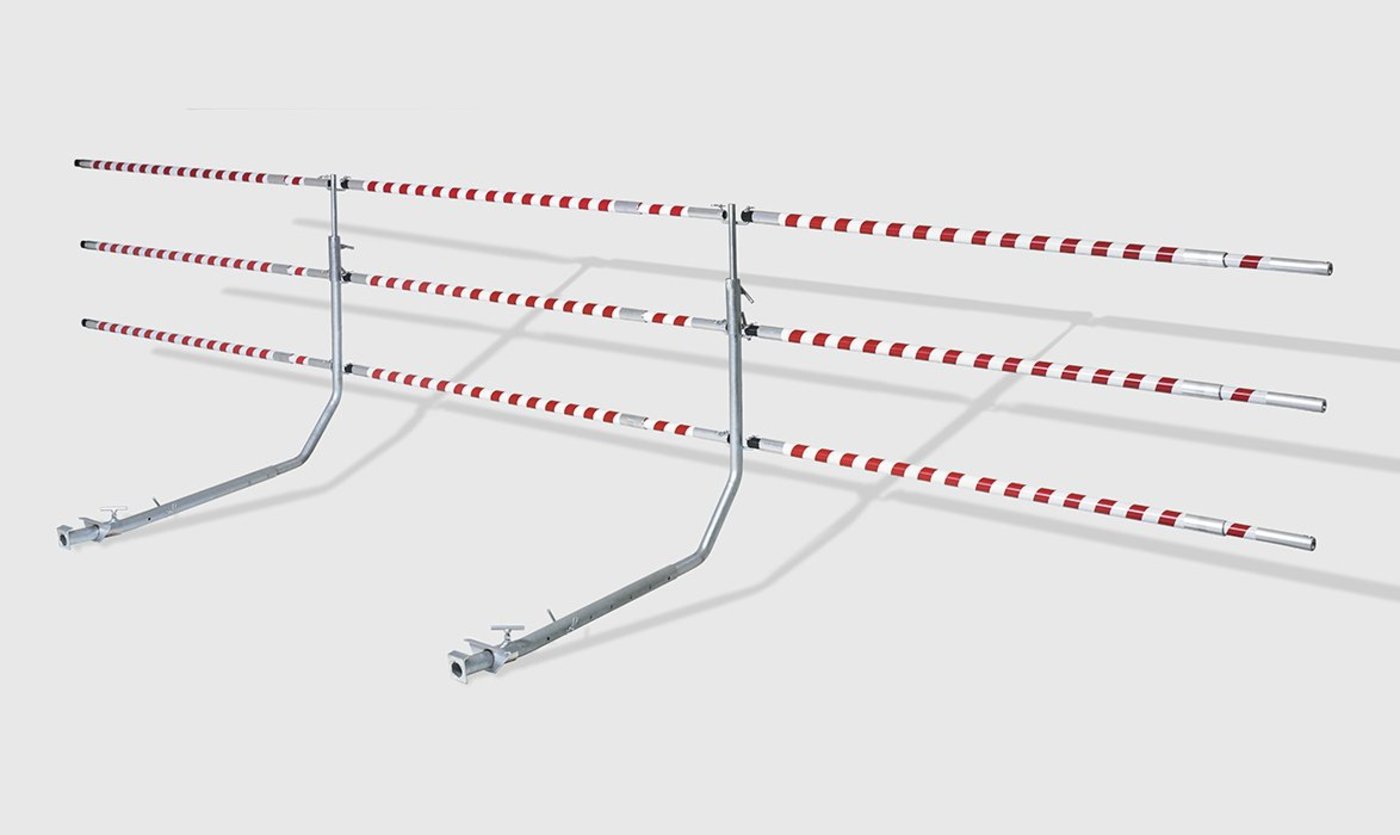

- Fixed barrier FA UPZ III

The fixed barrier FA UPZ III EN is certified according to the requirements of DIN EN 16704-2-2 and the DB specification sheet for fixed barriers, version 1.1, dated 1 March 2020 and is approved for use on DB Netz AG infrastructure with the technical railway approval dated 31 October 2020.

Technical railway approval | PDF for downloadKey details

- Incrementally adjustable hazard zone of 1.95 - 2.55 m / increments of 10 cm

- Telescopic cross beams of 1.80 - 3.00 m

- No major groundwork is needed beneath the fixed barrier due to the very small mounting bracket on the stand in combination with the 6° inclination of the stand

- Approved for use at sites with passing speeds of up to 160 km/h

- Slender, free-floating design without slope supports

- Cantilever and rail base design made from high-tensile, galvanised steel

- Telescopic beams made from aluminium with high rigidity and a low weight

- Suitable for all barrier types (incl. fixed tracks)

- Camber equalisation module as an extra

Advantages

- Low weight enables high transport quantities per vehicle and efficient logistics at the track

- Quick assembly thanks to robust design and limited number of fastening elements

- High stability despite the free-floating design

- Minimum maintenance and great flexibility in storage

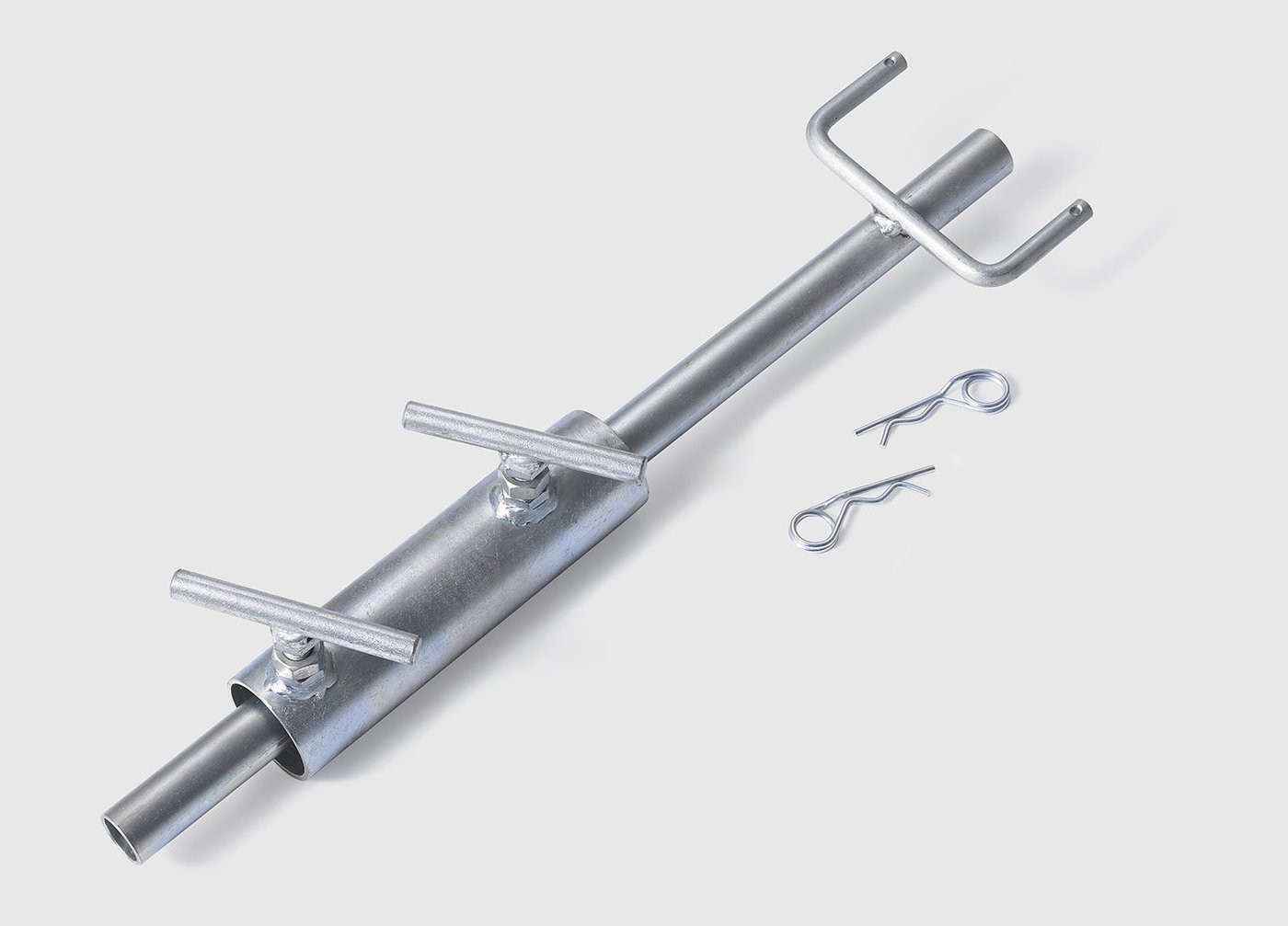

Components

- Rail base mount with slider and toggle screw

- Cantilever

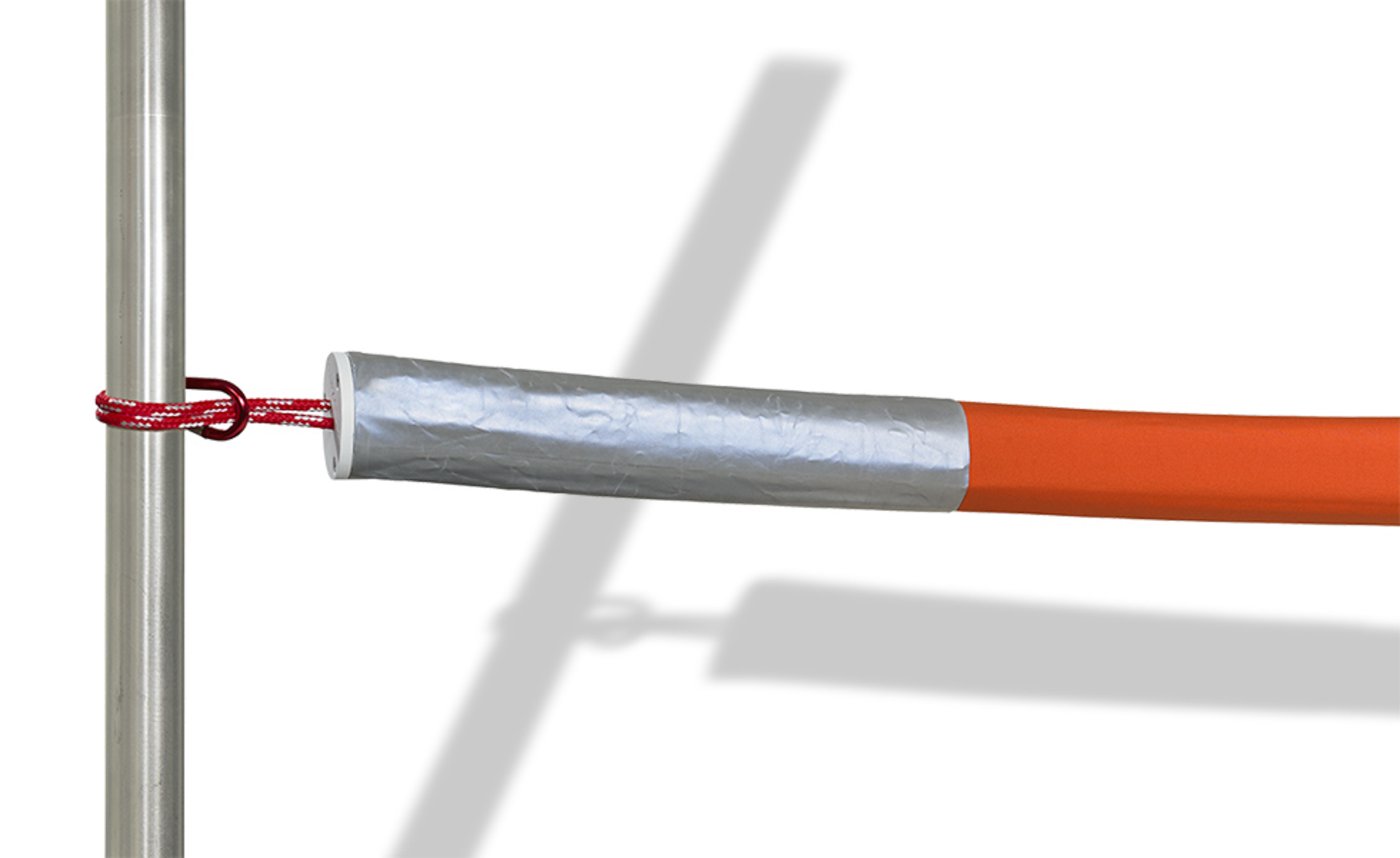

- Telescopic beam with warning notice and insulation piece

- Angle plug

- Cotter pin

Technical details

- Cantilever complete with rail base and rail base clamp approx. 7.7 kg

- Telescopic beams made from aluminium approx. 3.9 kg

- Weight of the overall system approx. 5.2 kg/m

- Electrical signaller ESG 3000 UPZ

UPZ developed the ESG 3000 UPZ as a replacement for the CO2 Typhon and as an alternative to all other electric horns.

Properties

- Signal volume 126 dB(A)

- Ergonomic and compact construction

- Low weight

- Long battery life

- Easy to handle

Components

- ESG 3000 housing with handle and carry strap, two exchangeable batteries and a single external charger for both

- Two key switches with keys and a 10 m long control cable with hand switch

- Upon request, we can also offer a stand, reserve batteries and reserve chargers

.

Technical details

- Weights: approx. 12.6 kg incl. batteries

- Batteries: LiFePo4 12.8 V 3000 mAh

- Charger: Li-Ion battery charger 14.6 V 2000 mAh

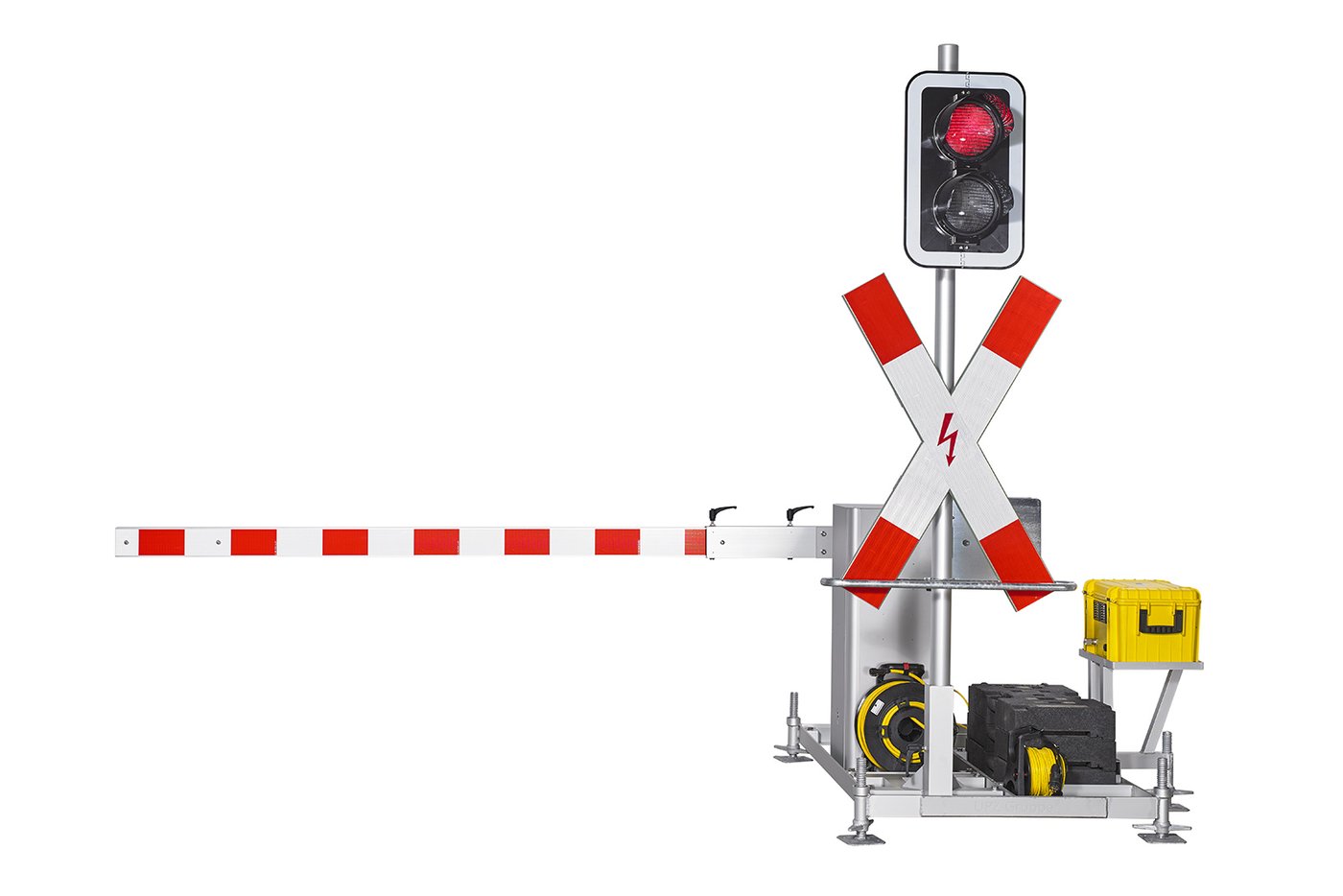

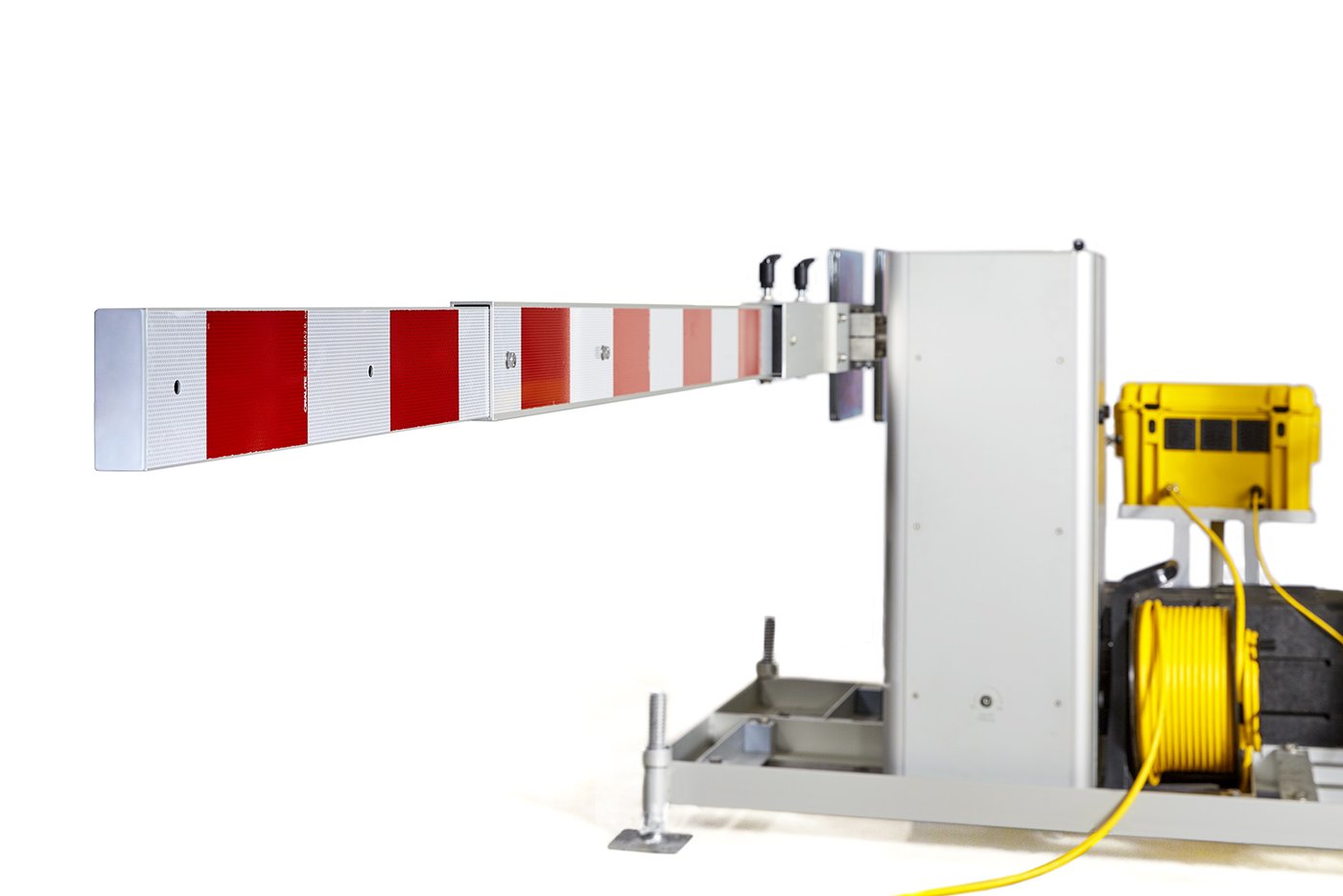

- Technical aid for crossing points (TH-BÜP UPZ) with integrated warning system

The TH-BÜP is a transportable, easy-to-install barrier system with a level crossing sign and integrated traffic light system for supporting crossing points, without auxiliaries. Using the TH-BÜP, it is possible to quickly secure crossing points at which permanently installed safety systems are temporarily disabled due to construction work. The TH-BÜP replicates the function, design and appearance of a permanently installed safety system. Thanks to digital control technology, the TH-BÜP offers extension and integration options according to the concept of Industry 4.0. Approval including warning system.

Approval including warning system by DB Netz AG since November 2018.

Approval by DB Netz AG for NWS as a PDF | Approval by DB Netz AG for TH-BÜP PDFTechnical details

- Power connector 230 VAC / 16 A / 50 Hz

- Power supply by 24 V DC system

- Max. number of traffic signals: 36 (3 per barrier drive mechanism)

- Number of crossing acoustic units: 12 (1 per barrier drive mechanism)

- Battery life 12 h in full use + 30 h red light

- Battery charging time 10 h after 12 h in full use

- 12.1” HD touchscreen

- Telescopic barrier boom 2.35 - 5.75 m

- Emergency closure function: based on rail contact or via push button on the control unit

- Warning system integrated into the control unit

- Operating temperature: 25 - 55°C

- Statics approved up to wind strength 10

Components

- Flexible, modular system size thanks to the combination of a control unit with up to 12 barrier drive mechanisms, with each up to 3 light signals and a crossing acoustic unit per barrier drive mechanism

- Easy-to-use system with a 12.1” HD touchscreen and key switch

- Display of all relevant system and status information for all connected components in real time and plain text

- Batteries with the latest lithium technology for unrestricted operation for up to 12 h without mains power supply and subsequent crossing safety function with red light for up to 30 h

- Easy to extend existing systems with additional components, e.g. barrier drive mechanisms or light signals – including during operation

- Recommissioning of debugged components with easy acknowledgement at the control unit

- Warning system integrated into the control unit with an emergency closure function based on rail contact

- Telescopic barrier booms of 2.35 - 5.75 m

- Closing direction (left/right) can be configured in the drive mechanism

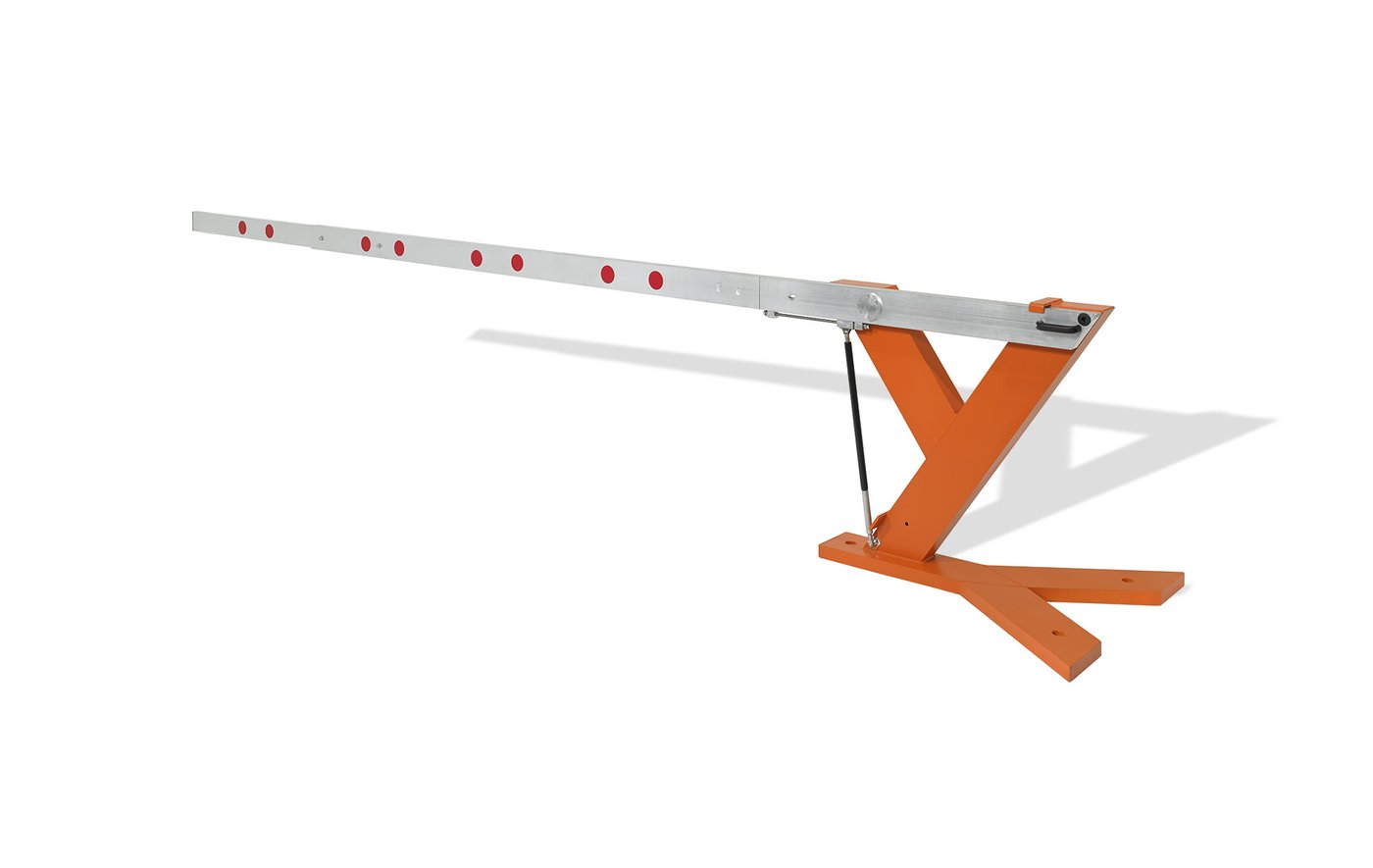

- Mobile temporary barrier UPZ MBS II

Mobile barrier system for setting up temporary rail crossings. The advantages of the UPZ MBS II include the quick assembly, variable barrier boom and ease of use.

Advantages

The system can be quickly and easily set up and is lockable. Signal dependencies can also be configured.

Properties

- Quick assembly

- Variable barrier boom (3.0 - 6.5 m)

- Easy to use thanks to gas pressure spring without counter weight

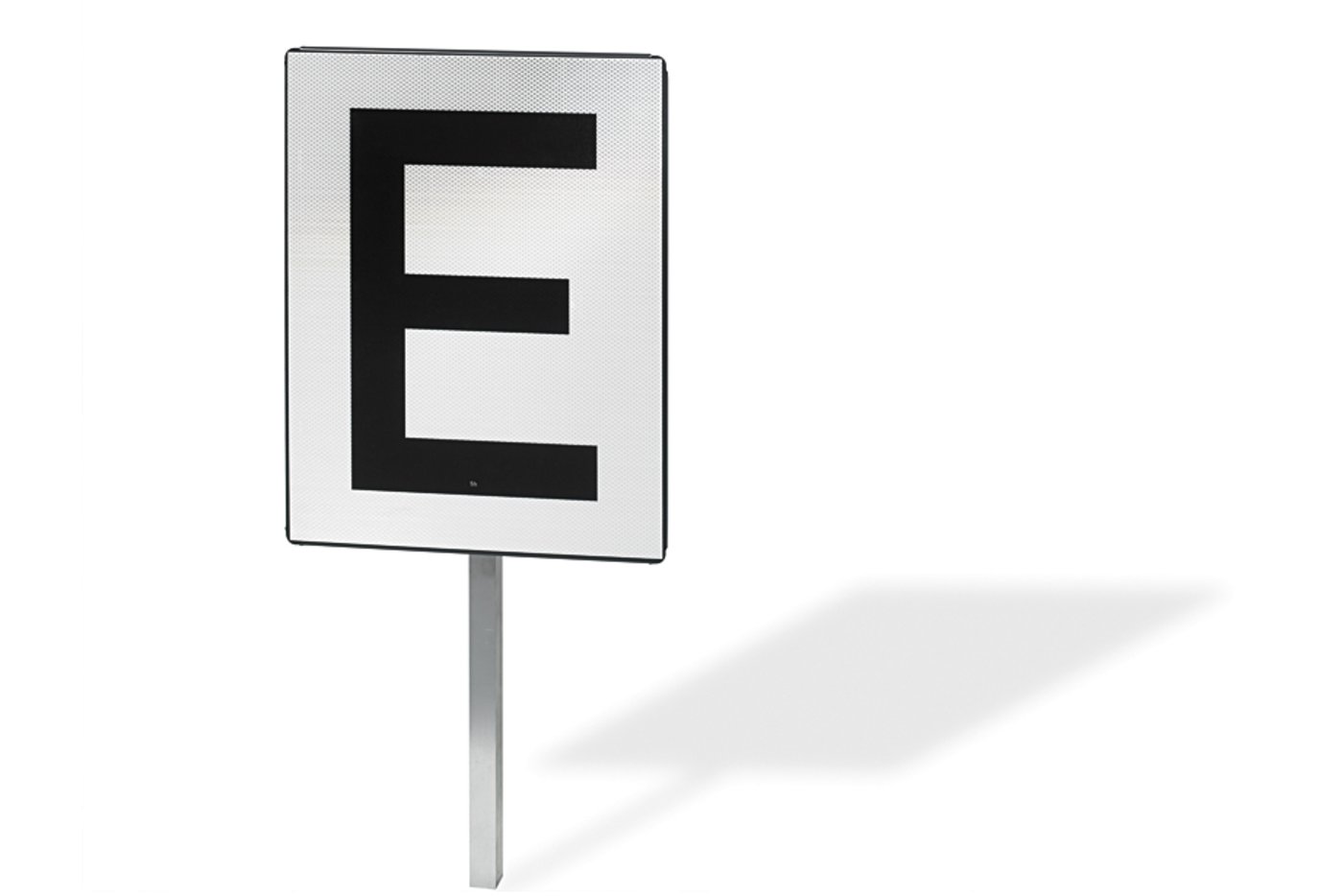

- Safety stop signal Sh2 · Type I, II and III

The Sh2 demonstrates high flexibility in use by the track as a dwarf signal (short or long) as well as post signal. Three different models are available depending on the application. We will be happy to advise you on the right model for your needs.

Technical noticesType I

The signal is quick to install and remove. This is particularly advantageous for shorter closure times. The inclination of the signal can be adjusted via the clamp screw on the respective rail type. Transport by car is possible thanks to the design. Approved for non-federal railways.

Comprising:

- 1 signal post, 6.5 kg, galvanised steel

- 1 signal board, 3.8 kg, reflective foil type 3, white with red overprint on both sides (for stop sign arrangement at the track), 540 x 430 mm

- 1 signal light, red (EBA approval)

Type II

This signal differs from the previous Type 1 in its highly stable rail base mount, but can still be installed quickly. It can likewise be transported by car when separated into two pieces. Approved for all railways.

Comprising:

- 1 signal post, 8.5 kg, galvanised steel

- 1 signal board, 3.8 kg, reflective foil type 3, white with red overprint on both sides (for stop sign arrangement at the track)

- 1 signal light, red (EBA approval)

Type III

This safety stop sign differs from the first two types due to its material and assembly flexibility.

Three setup variants:- Short dwarf

- Long dwarf

- Long post

Setup next to the track, with the light at the top and bottom

Properties

- Signal board, 3.8 kg, 540 x 430 mm, reflective foil type 3, white with red overprint

- Reverse side: black and yellow stripes (for arrangement next to the track)

- Long post, made completely from aluminium, 9.8 kg

- Long dwarf, made completely from aluminium, 4.4 kg

- Red signal light (EBA approval)

- End signal for dead-end line, bracket with signal board

Reflective foil, white with red overprint, reverse side black,

without lamp, weight: approx. 5.5 kg

- Signal mast system UPZ LF IV

The signal mast system UPZ LF IV is a modular system for setting up temporary speed restrictions in the area of railway systems. The compact design enables assembly by a single person. All approved signal boards and lights can be mounted. It can optionally be set up as a dwarf or post signal in accordance with the Code of Signals (ESO SB 301). The system is EBA-approved and has series approval of DB AG.

Technical noticesComponentsProperties

- Rail base bracket part 1 / part 2

- Signal mast part 1 / part 2

- Supporting carrier

- Slope supports (2 pieces)

- Extra: dwarf module, rail base mount part 1 as a tunnel module

Properties

- Weight of post variant approx. 25 kg (without boards and lights)

- Boards and corresponding accessories comply with the signal regulation for railway operations SB 301. All digits are possible as indicators.

- Provision of all signal boards pursuant to RIL30 possible on request

- Assembly is possible on gravelled tracks, most fixed tracks and in tunnels

- Air brake head UPZ LBK 2000

The air brake head UPZ LBK 2000 enables pushed, air-braked movements (shunting and train movements) to be brought to a halt by a person authorised to test brakes. Use of the air brake head is regulated by local provisions and requirements.

Technical noticesProperties

- Braking clutch head with integrated valve, mount, safety lever and an activation line

- Outdoor case (waterproof, shockproof and dustproof) is optionally available for secure storage and transport

Weight

- Weight with line approx. 1.25 kg

- L 230 mm | W 70 mm | H 90 mm

- Barrier strap

The barrier strap was developed as a durable alternative to conventional products available on the market. It is distinguished by high-performance elastomer that contracts the barrier strap to 20% of the nominal length. Continuous pretensioning prevents contact with the ground and significantly extends the lifespan. Weatherproof and washable contrast fabric and reflective material are used in alternating intervals of 500 mm. Our reflective material, which exceeds the highest performance level of the required minimum reflection values, reflects light in white. The angle of incidence has no effect on the colour reflected. Extra-large aluminium carabiners enable easy installation of the barrier strap.

Technical noticesTechnical details

Length: 2 m · weight: 0.7 kg

Length: 12 m · weight: 1.8 kg

Washable: handwash at 30° C without aggressive cleaning.The 12 m strap is adjustable in a length of 3 - 12 m. Additional products for supporting level crossings are likewise available. A set design with warning pyramid is possible. Prices available on request.

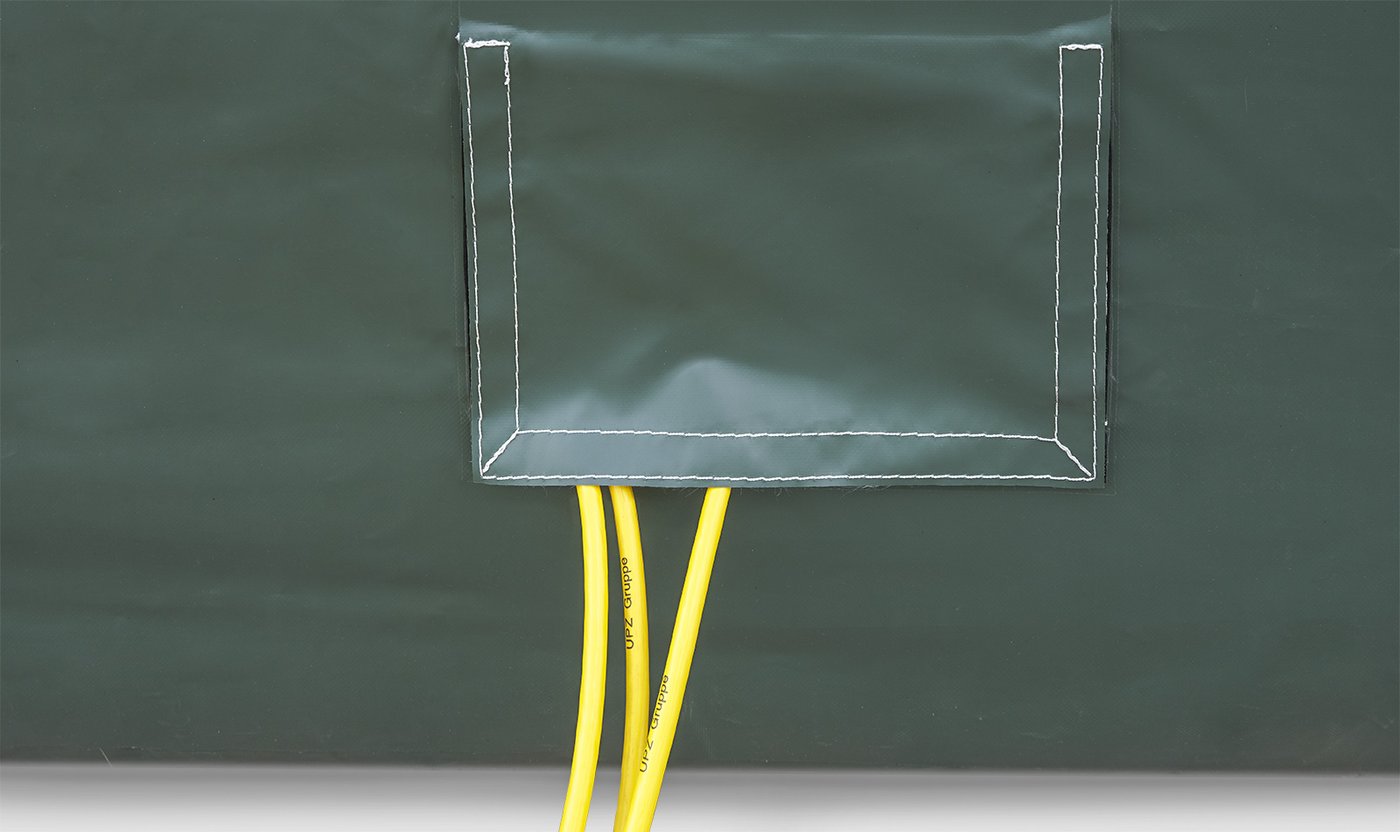

- Weatherproof shelter (inflatable)

Highly robust, mobile and inflatable weatherproof shelter made from high-quality plastic material for construction site personnel, for example at crossings. The weatherproof shelter has a floor area of 3 x 3 m and can be anchored to the ground for stability. When dismantled and deflated, the weatherproof shelter can easily be stored and transported in the bag provided. Moreover, a table, chair, lighting, 2 pumps (manual/electric) and a heater are included in delivery.

![Sh2 Typ III high [Translate to English:] Sh2 Typ III hoch](/fileadmin/_processed_/f/9/csm_SH2_125407_w_f0de1cae84.jpg)

![Sh2 Typ III short [Translate to English:] Sh2 Typ III kurz](/fileadmin/_processed_/4/9/csm_SH2_B_125421_4c4feae375.jpg)

![Safety stop signal Sh2 detail [Translate to English:] Signaltafel Detail](/fileadmin/_processed_/0/5/csm_SH2_125830_e722218a3a.jpg)

![Safety stop signal Sh2 · Type ! [Translate to English:] Sh2 Typ I](/fileadmin/_processed_/3/a/csm_SH2_Typ1_125391_658d27250b.jpg)

![Safety stop signal Sh2 · Type II [Translate to English:] Sh2 Typ II](/fileadmin/_processed_/5/1/csm_SH2_Typ2_125399_fa45e972a4.jpg)

![Sh2 Typ III high [Translate to English:] Sh2 Typ III hoch](/fileadmin/_processed_/f/9/csm_SH2_125407_w_708f293980.jpg)

![Sh2 Typ III short [Translate to English:] Sh2 Typ III kurz](/fileadmin/_processed_/4/9/csm_SH2_B_125421_987a2779b9.jpg)

![Safety stop signal Sh2 detail [Translate to English:] Signaltafel Detail](/fileadmin/_processed_/0/5/csm_SH2_125830_130630a0a6.jpg)

![Safety stop signal Sh2 · Type ! [Translate to English:] Sh2 Typ I](/fileadmin/_processed_/3/a/csm_SH2_Typ1_125391_90d0631154.jpg)

![Safety stop signal Sh2 · Type II [Translate to English:] Sh2 Typ II](/fileadmin/_processed_/5/1/csm_SH2_Typ2_125399_51ab66e82f.jpg)